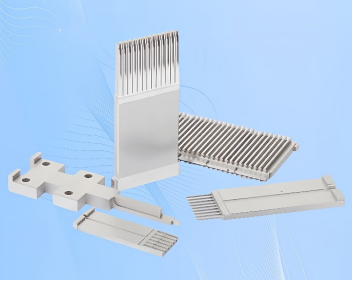

Connector mold parts

High - Precision Connector Mold Parts by Dongguan Aoshuo Precision Mould Co., Ltd.</h1>1. Company Introduction</h2>Dongguan Aoshuo Precision Mould Co., Ltd. was established in 2008 and is located at No. 1, Xinchun Road, Shangsha, Changan Town, Dongguan City, Guangdong Province, China. As a comprehensive mold parts supplier, Aoshuo specializes in the design and processing of high - precision mold parts and automated precision components. With advanced technology and rich industry experience, our products are widely used in various fields such as precision stamping molds, plastic molds, automotive molds, medical molds, precision computer connector molds, medical devices and equipment, and jigs, enjoying a good reputation in the industry.2. Core Business Overview</h2>Aoshuo's business scope is extensive and diverse. The connector mold parts business is one of its core businesses. In addition, our rich business portfolio also includes:Mold Processing: We offer a variety of products suc

High - Precision Connector Mold Parts by Dongguan Aoshuo Precision Mould Co., Ltd.

1. Company Introduction

Dongguan Aoshuo Precision Mould Co., Ltd. was established in 2008 and is located at No. 1, Xinchun Road, Shangsha, Changan Town, Dongguan City, Guangdong Province, China. As a comprehensive mold parts supplier, Aoshuo specializes in the design and processing of high - precision mold parts and automated precision components. With advanced technology and rich industry experience, our products are widely used in various fields such as precision stamping molds, plastic molds, automotive molds, medical molds, precision computer connector molds, medical devices and equipment, and jigs, enjoying a good reputation in the industry.

2. Core Business Overview

Aoshuo's business scope is extensive and diverse. The connector mold parts business is one of its core businesses. In addition, our rich business portfolio also includes:

Mold Processing: We offer a variety of products such as hardware stamping mold parts, pressing mold parts, and PG seeds.

Plastic Mold Parts: These are mold components suitable for the production of various plastic products, meeting the production needs of different plastic products.

Semiconductor Components: Covering alloy chucks, tungsten steel fixture plates, winding molds, magnetic powder molds, tungsten steel wire nozzles, tungsten steel molds, and tensioners, etc., providing professional accessories for the semiconductor industry.

Fully Automatic Winding Alloy Chucks: An automated solution that significantly improves production efficiency, helping enterprises increase production benefits.

Precision Injection Mold Spare Parts: Ensuring the accuracy and stability of the injection molding process and guaranteeing the quality of injection - molded products.

Automation Components: All kinds of precision components that support industrial automation and promote the process of industrial automation.

Hardware Stamping Mold Spare Parts: High - quality hardware stamping parts suitable for mass production, meeting the needs of large - scale production.

3. Connector Mold Parts Details

3.1 Product Positioning

Aoshuo's connector mold parts are customized specifically for the electronics industry, aiming to provide high - precision connector solutions for electronic devices. In the electronics industry, connectors are indispensable components in electronic devices, and their accuracy, stability, and reliability directly affect the performance and quality of electronic devices. Aoshuo is well - aware of this and, with its own advantages, provides high - quality connector mold parts for customers in the electronics industry.

3.2 Product Features

High Precision: Aoshuo's connector mold parts perform outstandingly in terms of precision. Through advanced processing equipment and exquisite processing techniques, we can meet the strict requirements for high - precision connectors in the electronics industry. Whether it is fine dimensional tolerances or complex structural designs, we can manufacture them accurately, ensuring stable electrical connections of connectors in electronic devices.

Strong Stability: During the production process, we strictly control every link, from the selection of raw materials to the control of processing techniques, all following high standards. We use high - quality materials, such as steel from well - known brands in Japan like Daido, Hitachi, and ASSAB in Sweden, to ensure the stability of products. After strict quality inspection, we ensure that each connector mold part can work stably in various complex environments, reducing equipment problems caused by connector failures.

High Reliability: With years of industry experience and technical accumulation, Aoshuo's connector mold parts perform excellently in terms of reliability. From the design stage, we fully consider various situations in the actual use of the product and conduct optimized design. Through advanced software simulation and actual testing, we continuously improve the product to enable it to maintain reliable performance during long - term use, providing a strong guarantee for the stable operation of electronic devices.

3.3 Production Advantages

Advanced Equipment: Aoshuo is equipped with a series of advanced production equipment, such as Makino and Beijing Jingdiao CNC machining centers. These equipment have high - precision processing capabilities and can achieve the processing of complex shapes. At the same time, we also have imported Japanese equipment such as Mitsubishi and Sodick, ensuring extremely high - precision requirements when processing connector mold parts. The application of these advanced equipment provides a solid hardware foundation for the production of high - quality connector mold parts.

Advanced Software Application: In the design and production process, Aoshuo uses advanced software such as UG, Pro - E, and AutoCAD for accurate design and simulation. Through these software, we can comprehensively analyze and optimize the structure and performance of the product in the design stage, identify potential problems in advance and make improvements. At the same time, during the production process, we use software for programming control to ensure the accuracy and consistency of processing.

Professional Team: Aoshuo has a professional team that follows up from the customer consultation stage. Team members have an in - depth understanding of the special needs of customers in the electronics industry and strictly control every link in the production process. Whether it is mold design, processing, or quality inspection, it is handled by experienced professionals. They have solid professional knowledge and rich practical experience, ensuring that the finally delivered connector mold parts meet or even exceed customer expectations.

3.4 Application Areas

Aoshuo's high - precision connector mold parts are widely used in fields such as precision computer connector molds. They can be found in computer motherboards, graphics cards, hard drives, and other devices. Their stable performance and reliable quality ensure the stable operation of computer equipment. At the same time, they also have a wide range of applications in other electronic devices, such as mobile phones, tablets, and communication equipment, contributing to the development of the electronics industry.

Copy product links

Copy product links

Long by picture save/share

Long by picture save/share

INQUIRY

Inquiry Content:

You have no items to require

Add Successfully

INQUIRY

Inquiry Content:

You have no items to require

Add Successfully